Lean BBS Internal Consultant Certification Workshop: Become a Lean Behavior-Based Safety Expert for Your Organization

Workshop Investment (cost) $2,495 per attendee until 45 days in advance, then $2,795 per attendee

-

*Recommended Option: Workshop attendees interested in licensing the materials may contact ProAct Safety to obtain a quote for a site, division, or corporate-wide useage. To ensure success, materials should be customized to reflect the unique culture of the location and details of the process. Handout materials are provided for seminar use only and may not be copied or distributed. Electronic materials are not included.

-

*This workshop is only available to end users. No consultants, agencies or other safety service providers are permitted to attend.

Discounts

-

5-9 people = 10% off registration

-

10-19 people = 15% off registration

Workshop Leader Shawn M Galloway, CEO

Schedule Day 1: 8:30-16:00 / Day 2: 8:30-15:30, lunch included

*Event venue will be confirmed at least 45 days prior to the workshop.

**See full event schedule for events offered consecutively with this workshop.

Workshop Description

The Lean BBS Internal Consultant Certification Workshop is designed for organizations that desire to internalize and sustain their own approach to Behavior-Based Safety (BBS). ProAct Safety has successfully certified over one thousand Internal Consultants across every major industry.

This intensive, highly interactive workshop will fully qualify attendees to return to their organizations and design a customized plan to strategically implement a new or improve an existing Behavior-Based Safety process. This approach is ideal for companies who want to maximize their own ability to implement the most effective and efficient approach to BBS, regardless of challenging industry or logistics, or who want to ensure a proven approach to find new sustainable results while minimizing outside costs.

Recommended: It would be helpful if each attendee read or listened to the book Lean Behavior-Based Safety: BBS for Today's Realities before the event to streamline conversations and expedite the learning process.

Creating Internal Capabilities

This workshop will train participants to utilize ProAct Safety's proven Lean BBS methodologies for facilitating an implementation. Most importantly, it will prepare the attendees to anticipate and address the issues that can challenge the success to behavioral approaches. Participants will be able to identify opportunities to minimize the perception of change, achieve the quickest success possible, and ensure long-term process sustainability. This approach is much more than a train-the-trainer course, which are typically intended to teach individuals to simply deliver training. Every site will have its own unique challenges and cultures. To allow internal consultants the most opportunities for success, it is extremely important they understand and internalize strategies to identify site-specific issuesthat have become, or could become, problematic barriers.

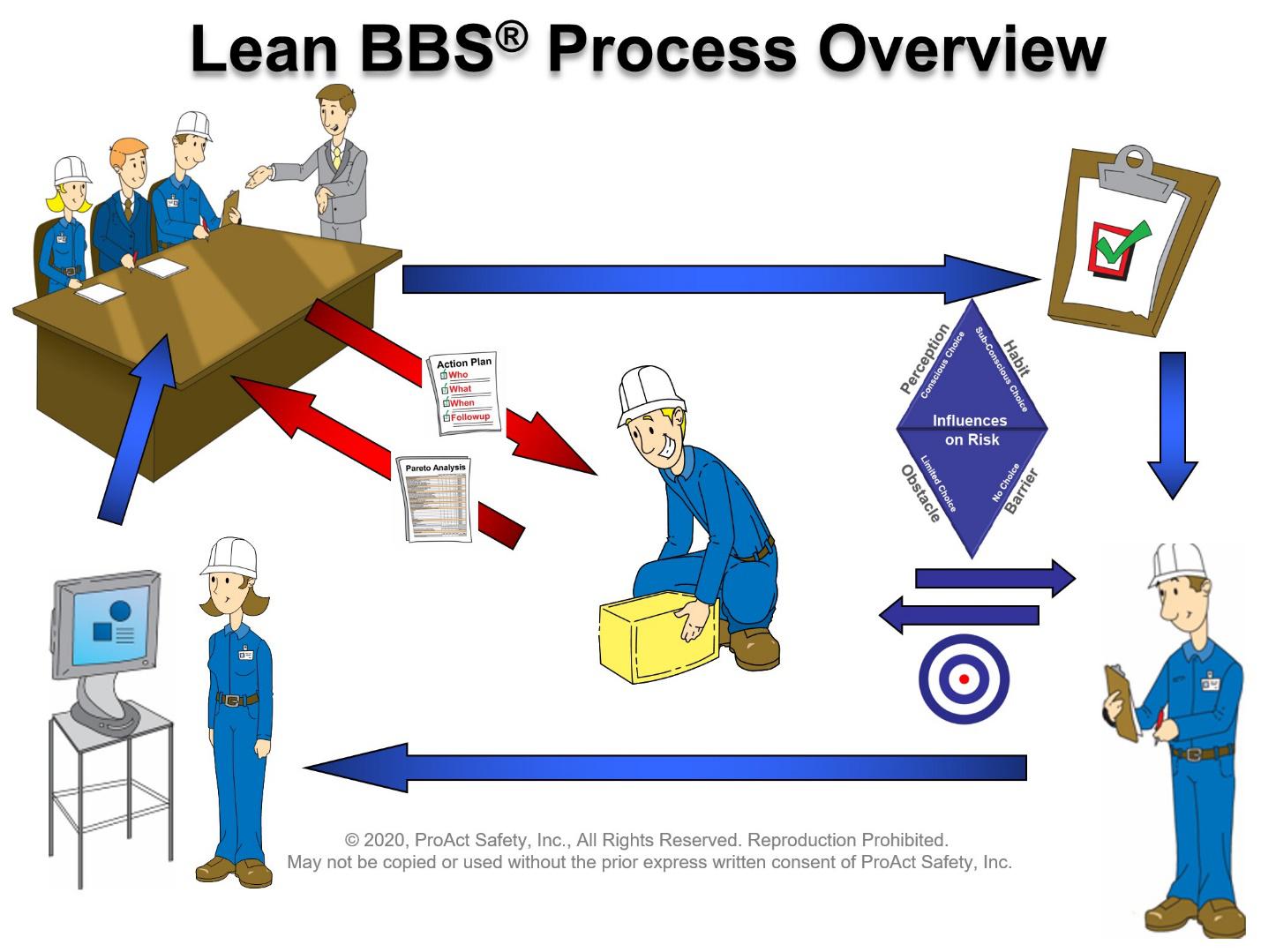

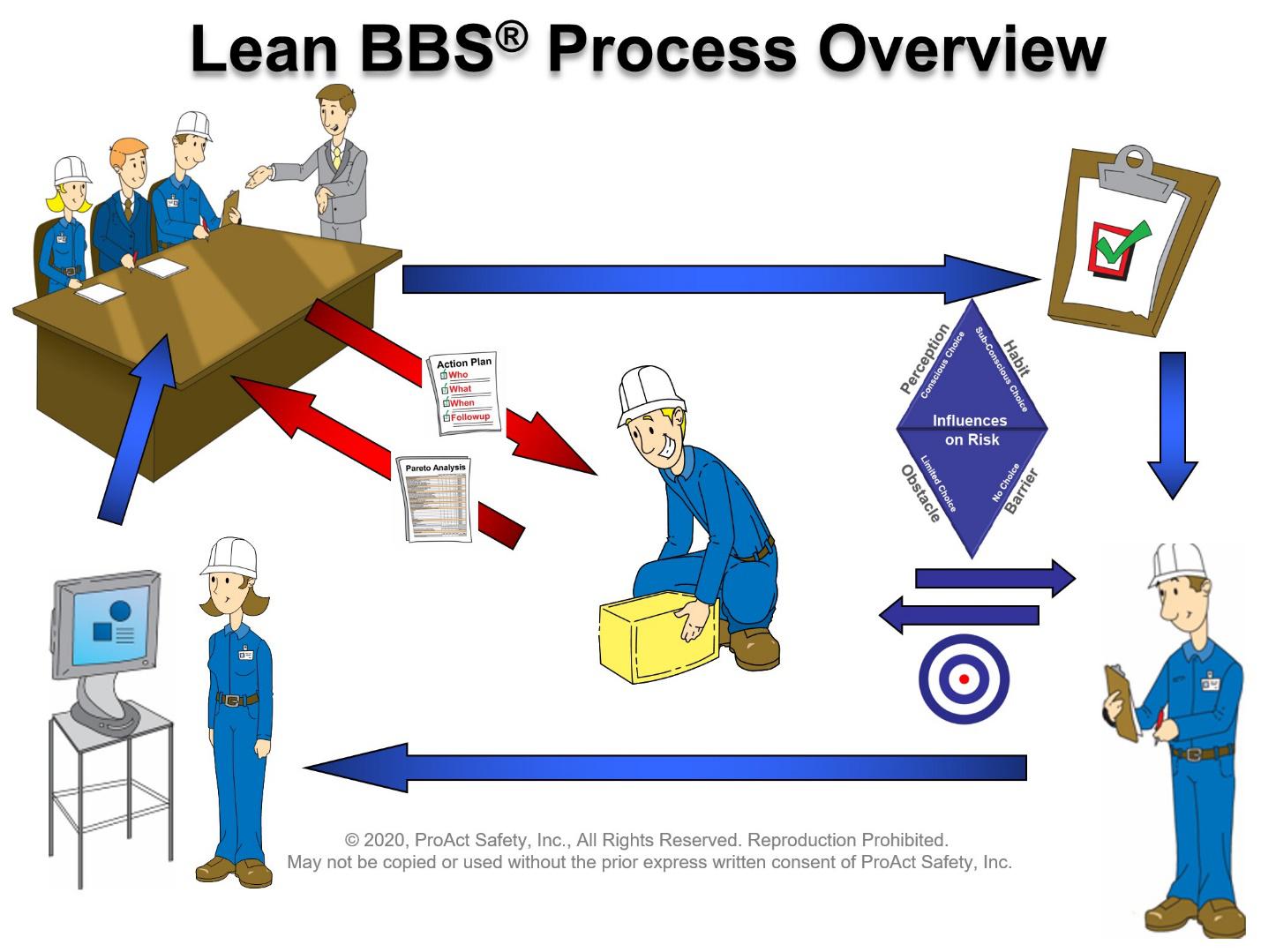

Lean BBS utilizes aspects of performance and quality systems to drastically reduce the typical internal resource requirements of a BBS process. Lean Behavior-Based Safety® focuses on leveraged use of resources resulting in quicker and more sustainable results in a shorter time, with less disruption to operations, and less resistance from workers and unions.

Learning Objectives:

- Learn to conduct an assessment to determine site readiness for behavioral approaches.

- Draft a strategic plan to customize implementation of BBS.

- Understand how to appropriately select steering team members and observers.

- Manage and coach the team through a BBS implementation or expansion.

- Ensure site leaders understand the process and adapt it to the specific needs and culture of the site.

- Develop a site-specific checklist or focus of behaviors and precautions which will have the greatest impact on accident prevention.

- Choose from multiple observation and feedback strategies to ensure a customized approach that best fits your organization and challenges.

- Build a management-support infrastructure to ensure long-term success.

- Hold kickoff activities to start the BBS process.

- Monitor and audit the process to keep it on course.

- Continuously improve the process.

- Leverage Human and Organizational Performance (HOP) and Safety Excellence Strategic Thinking to create recognizable value, focus, engagement, and feedback systems with minimal resistance and waste.

Advanced Elements:

- Change Management — The psychology of resistance to change, and how to avoid creating resistance.

- Culture Change Strategies — A best practices approach.

- Advanced Assessment Strategies — Developing quick wins.

- Building understanding and support for the BBS process prior to assessment or implementation.

- Strategic options for implementation that customize the process to the site culture.

Re-energize Your Existing BBS Process

It is unfortunately common to see results from many traditional Behavioral Safety processes plateau after the first two to three years of operation. At that point, the process can become routine and lose the original result-based orientation. The successes that motivated the process early-on disappear and the entire process tends to slowly lose momentum. Successful BBS processes do not typically fade away, but can be much less effective than they are capable of being. This is the perfect time for BBS process improvement. Improvement strategies can accomplish several important objectives:

- Attain the next step in accident-reduction results through better targeting.

- Increase the level of expertise in personnel active in the process.

- Integrate new techniques to enhance existing observation and data analysis strategies.

- Re-energize the process utilizing Lean BBS techniques to improve results and increase employee participation.

- Reduce manpower requirements to maintain the process.

- Assess the existing Behavior-Based Safety process for foundations to build on.

- Make more efficient use of site leaders and steering teams.

- Narrow the focus of the checklist to improve efficiency.

- Focus observations where they will produce the best results.

- Learn tactics for continuous process improvement to ensure process sustainability.

Certification through ProAct Safety, Inc. is valid for 3 years following the workshop. Internal Consultants must attend refresher training to discover advances in approaches and maintain certification. Locations where Internal Consultants implement Behavior-Based Safety processes must be covered under the Training Materials License agreement.

REFUND & CANCELLATION POLICY: We reserve the right to cancel an event up to 30 days in advance, in which case a full refund applies. Attendee may cancel registration up to 60 days prior to an event, in which case a full refund minus 3% administrative fee applies. Cancellations under 60 days to two weeks prior to the event receive a 50% credit for future use. Credits can be used for one full year from original event date for any event, product or subscription purchases. After one year, all credits expire. No refunds or credits apply to cancellations less than two weeks in advance.

Any event cancelled due to Force Majeure will be refunded minus processing fees, or issued as a full credit to be used for attendance at other ProAct Safety public or private events or for copies of published books, whichever the customer chooses.

CONTINUING EDUCATION: This event qualifies for CM or COC credits toward

maintaining accreditation. Attendees may request documentation after the

course is complete.