Safety 2006 Proceedings - June 2006

By: Terry Mathis, ProAct Safety and Thomas Burns, AstraZeneca

Printable Version

Introduction – “Being the Best”

In 2003, AstraZeneca, Westborough (AZWB) planned, developed and implemented the BEδT* (Building Excellence in Safety (SHE) & Quality Together) Program. BEδT is a far-reaching, behavior-based program aimed to improve two vital aspects of a pharmaceutical manufacturing site: SHE and Quality compliance. The foundation of AZWB’s BEδT program is an innovative partnership between two unlikely organizations, Quality Assurance (QA) and Safety, Health and Environment (SHE). SHE and Good Manufacturing Practices (GMP) are core to AstraZeneca’s business, and we believe that BEδT will ensure that our employees never lose sight of our aspirational goal of zero accidents and incidents (Target Zero) and Right-First-Time (100% quality compliance). The program has required a team approach and active participation by employees from diverse backgrounds.

There are several reasons why AZWB chose to invest in the BEδT program. Some of these reasons will become more apparent after first taking a step back to review where we’ve been as a site and the challenges ahead.

*The Greek letter “δ” (delta), used commonly to represent change, was chosen as a hybrid of the combined “S” & “Q” in our acronym. Ironically, Westborough’s BEδT program was defined and named prior to AstraZeneca’s Being the Best campaign.

Background

Since the Astra - Zeneca merger in 1999, the AstraZeneca Westborough Supply Site has undergone a tremendous transformation, not only in our overall business performance, but in our SHE performance as well. Statistically speaking, AZ Westborough has demonstrated exceptional SHE performance improvement over the past three or four years. While this is great news for our employees and the site, it has presented the SHE team with an interesting challenge. How do we maintain or improve on the current performance trend? And from a practical standpoint, do the statistics reflect reality? Finally, on both levels, how do we demonstrate continued SHE performance improvement going forward? What, if anything, do we need to do differently?

When further defining this issue, the SHE team in Westborough recognized:

We were at a point where statistical SHE performance improvement was starting to “plateau”,

A minimal uptick in injury or illness incidence at first glance may have given the appearance of declining SHE performance,

From a practical standpoint, we were confident that there was still a good deal of room for improvement,

While SHE remained a key element of our culture at the site, it was not yet fully integrated into the business,

Initiating any new SHE programs, as “stand-alone” initiatives in the midst of good SHE performance may have not been well received by employees or may have been perceived as “just another SHE program”,

And more importantly, we needed an innovative approach.

The Way Forward

Reaching our vision of Being the Best in SHE meant taking a new approach - recognizing the possibility that incremental improvements in performance could not be achieved using the same methods and thinking that gave us the level of performance we have today. The way forward involves a more innovative, business-integrated, customer focused mindset. Success will only be achieved when SHE is perceived by our internal and external customers as a true business partner. The way forward will be likened to an overtime period in a ball game, when winning is derived from renewed energy, exceptional teamwork, and even a new strategy. Anything less gets you no better then a tie game.

With all of this in mind, in 2003 we took some important steps to position ourselves for achieving our vision for Being the Best in SHE. To be the best in safety we’ve implemented the BEδT Program, a combined safety & quality compliance behavior-based process. To be the best in health we’ve taken a collaborative approach to both educate employees on AstraZeneca products and managing health issues. To be the best in environmental performance we’ve mitigated the risk of pharmaceuticals in the environment while saving energy. In the pages to follow, we will focus on our behavioral approach in safety and quality – a new way of operating which has put us on the path to Being the BEST.

Being the Best in Safety & Quality Compliance

The traditional approach to improving safety has been to conduct an investigation (after the fact) to determine the cause of an accident. To illustrate this, consider an analogy as depicted below, of an employee falling from a cliff (Exhibit 1). In this analogy, an accident investigator would pose such questions as, “why did the employee fall off the cliff?’ and “how can we prevent that from happening again?”. Our measure of success going forward was defined by the number of employees who “fell off the cliff”, a lagging performance indicator. To be the best in safety, we need to llok beyond this traditional approach. BEδT is an effort to do just that.

How do we change the probability of someone falling over the edge? We need to gain a profound knowledge of our behaviors. We need to move to the top of the cliff and measure how many employees get too close to the edge and more importantly, determine why they were too close. In doing this we are measuring at-risk behaviors before they become accidents. By understanding "why", we are able to change behaviors that can cause accidents.

Exhibit 1. This is the cliff analogy.

The same traditional approach exists in performing quality compliance investigations, i.e. conducting an investigation (after the fact) to determine the cause of a process deviation or problem. This presented an opportunity to partner with QA to use a common method for achieving our mutual goals – target zero and right-first-time.

External Partnership

To assist with the design and implementation of a customized solution, AstraZeneca solicited proposals from a handful of the top behavioral safety specialists in the U.S. One of our key goals was the willingness of the organization we chose to take a truly ‘custom’ approach. We felt strongly that an off-the-shelf process would not work well at our site. After several weeks of review and discussion, AstraZeneca chose ProAct SafetyTM, Inc. ProAct SafetyTM offerred the right balance of flexibility in approach and value.

ProAct SafetyTM

When AstraZeneca first contacted us, a strategic committee had already considered the possibility of combining quality and safety into one initiative. It was obvious that this was not just another site looking to reduce their accident rates. The Site leaders had clear goals and solid expectations and were seeking a partner to test the feasibility of their vision and turn it into a successful reality.

We quickly determined that this project would not only stretch the boundaries of traditional behavior-based safety, but would challenge the very model of consulting under which such processes are normally delivered. The challenge was more than offset by the opportunities for innovation and the even more illusive opportunity to form a true collaborative partnership between a client and consultant that exists more in marketing materials than in the real world.

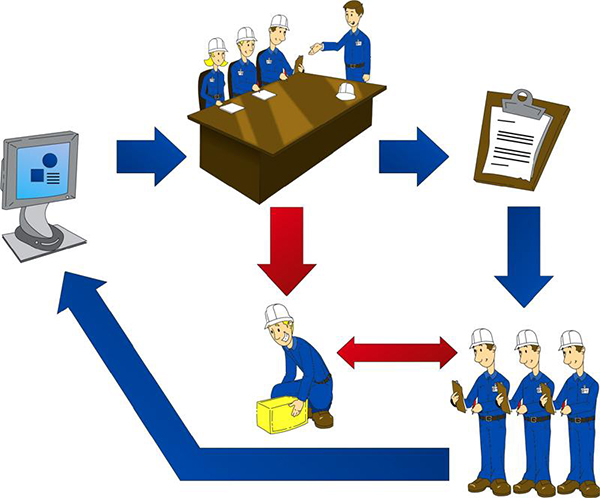

The flow of the implementation was a modified BBS process flow; but the steps had significant variances. The makeup of the Steering Team straddled safety and quality employees. The development of the checklist involved the review of massive amounts of quality-assurance data to determine behaviors that most impacted right-first-time goals and outcomes. The Steering Team spent time considering whether or not it was feasible to observe for both safety and quality data at the same time in all locations. For this and other reasons, the Steering Team elected to perform sample observations for two months before finalizing their observation strategy.

Even then, the newly selected and trained observers were required to bring Steering Team members with them for the first month to ensure that the strategy was followed and working. When the observers were rotated, Steering Team members accompanied the old and new observers for another month to help smooth the transition and maintain the integrity of the observation strategy.

During the first year after process kickoff, the Site Manager was reassigned and the site received a new General Manager. He was not only an acceptable replacement, but actually expanded the support among managers with new insights on how the process could be more successful.

Readiness Assessment

The first step in the process was to perform an organizational assessment to determine the site’s readiness for using a behavior-based approach. Focus groups, perception surveys, and existing data analysis revealed that AZWB had an ideal climate for accepting behavior-based solutions.

Strategic Planning

Two teams were formed to design, develop & implement a customized process for the site (Appendix A). A Strategy Team set objectives, defined critical success factors, allocated resources, and established boundaries for developing the process. A Steering Team, made up of members who met specific leadership criteria, was chartered to customize and implement the plan. Process advisors from Quality and Safety provide ongoing coaching & guidance to this Steering Team. Consultant training centered on this later team who learned the process and designed tactical elements of the process.

Management Commitment

Early communication and frequent briefings were conducted to ensure that Managers and Supervisors understood the overall scope and resource needs of the process. As Managers learned the details of what their Steering Team had designed, they engaged in defining their own support behaviors to ensure the success of the process. Management buy-in was critical to the success of the process.

Training & Implementation

The Steering Team training and development curriculum included basic team skills, introduction to behavioral science, process design, data analysis and problem solving, observer training, and navigating long-term process issues. Over 80 hours were devoted to ensuring the team had the competence and confidence to effectively implement and manage this process.

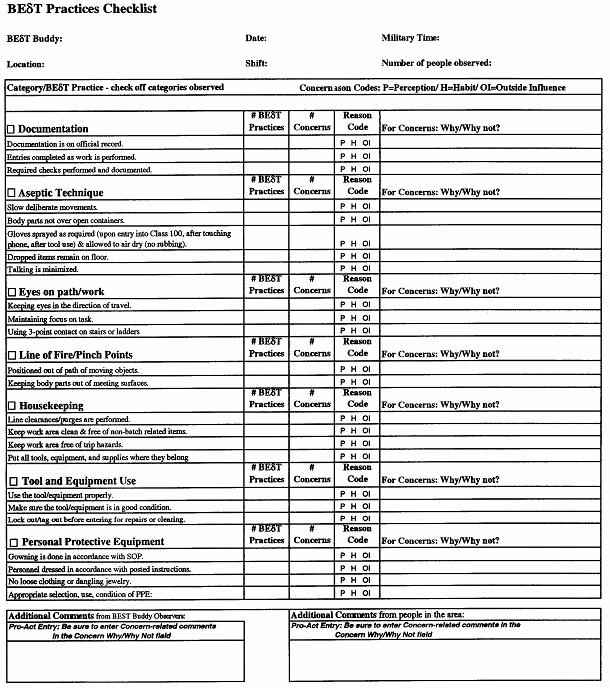

A BEδT Practices Checklist identifying the site’s critical behaviors was developed by analyzing two years of accident & quality data (Appendix B). The team piloted the process so that we could better understand the observation-feedback element. Their experience enhanced their ability to train and mentor our initial observers, known locally as ‘BEδT Buddies’.

Site-wide employee briefings were provided to coincide with start of the pilot. The key objectives of these 2-hour sessions were to:

Introduce BEδT and the behavior-based methodology;

Present the business case for implementing it at AZWB;

Help reinforce that observations are anonymous – we are only looking for the “what”, “how”, and “why”, not the “who”;

Demonstrate the importance of feedback in understanding & changing behaviors;

Solicit volunteers to be the first group of BEδT Buddies.

Exhibit 2. This is the BEδT Logo.

Thirty-seven BEδT Buddies were screened and selected, and represented all shifts and major areas at this site. They initially received 4-hours of formal classroom training, which is typically the base training for observers. However, based upon the challenges encountered during the pilot, the Steering Team implemented an innovative solution by providing intensive on-the-job training and mentorship for the BEδT Buddies.

The Process in Motion

Since September 2003 (the start of our formal data gathering), we have logged over 7,500 observations involving over 21,000 people observed that provide a solid baseline from which to focus our continuous improvement efforts. Of the seven categories contained on the checklist, four behaviors (2 quality and 2 safety) were identified early on as “quick wins” – defined as having a measurable impact and being achievable within a short timeframe. The team communicated these initial findings to the site and developed action plans to address them.

Process Evolution

After the first 12 to 18 months of working the process and to ensure continuous improvement, there was the need to refocus the efforts. In early 2005, the team undertook an effort to “Narrow the Focus” of the overall process. The critical behaviors checklist which served well in the early days of data collection was in need of updating.

Safety and Quality data from the past year and a half was reanalyzed and used to shorten the critical behaviors checklist. The site was able to eliminate some behaviors where it was felt they had sufficient data and were observing consistently high percentage of best practice, in lieu of some focused observations. For safety improvement, critical behaviors associated with lacerations and glass handling was added and greater focus was placed on aseptic technique, for quality compliance.

Innovative New Uses

During the past year, we have begun to use the observation process for discrete projects with some great success. During the site’s annual maintenance shutdown, a four week time period where all production and systems were taken down, refurbished and updated, the process was used for contractor safety surveillance.

A special critical behaviors checklist was developed, mirroring OSHA's top construction safety issues. AstraZeneca project managers took on the role of observers, using this checklist and were able to provide weekly snapshots of individual contractor team performance opposite these behaviors. At first, the use of this process was met with some skepticism. It was new to most of the contractors. It quickly became somewhat of a contest among the contractors, to see who could end up with the highest % of best practices in the weekly lunch meetings that were held with the superintendents/foremen.

Also, we are using the process for large capital construction projects (a new Microbiology Lab construction). This approach was certainly new to our construction contractors, but is now well received and a useful, real-time method for identifying concerns and putting actions in place to prevent incidents, mishaps and issues which can be costly and time-consuming.

Conclusion

The process had a great initial impact on the site’s performance, reducing accidents with injury by 50% and contributing to a 17-point rise in pristine batches, a measure of quality right-first-time. In recognition of these achievements, AstraZeneca awarded the Westborough site the Chief Executive’s SH&E Award for 2004.

The process has proven its adaptability in use on discrete projects and continues to challenge the site to make other and better uses of its ability to focus workers on the behaviors that produce results in targeted areas. The site is exploring options to better integrate the process into the business units to garner increased ownership and local control of the checklists and observation targets.Over time, this process will improve and transform our critical behaviors and ultimately help us achieve our goals of Target Zero and Right-First-Time.

Illustrations

APPENDIX A: BEδT Program – Basic Process

APPENDIX B: BEδT Practices Checklist